Rotomolding is really a much used industrial action since it is extremely affordable. Its main objective is to Plastics Rotomolding model polymers, modifying them into thermoplastics. The most common polymers are PVC, polyethylene, and polypropylene in this kind of exercise.

Different businesses can create from your most basic to really complicated resources throughout the rotational molding approach. Also, according to the reason for the plastic materials, this is a more prevalent option than options including blowing, injections, and vacuum procedure.

Rotational Molding is a method that permits the production of straightforward materials plus a higher level of complexity. These pieces are hollow and airtight, small, just like a coin, or huge, like 25,000-liter tanks.

In this sort of bit, the recurring challenges are usually little because of the deficiency of strain on the resin. This process also takes care of the creation of inserts, threaded elements, gussets, double walls, pockets, and openings enabling supplies and colors to be easily changed.

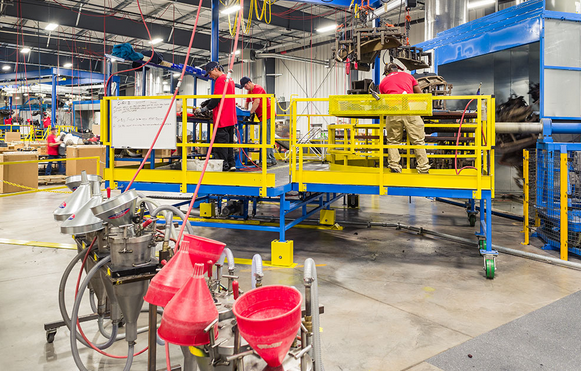

An entirely controlled process

To achieve superior quality elements using a adequately-managed procedure, you must have specialists. Granger Plastic materials Firm is the perfect partner for companies that want the most effective plastics merchandise.

The equipment and molds used in Plastics Rotomolding are much cheaper than other molding operations. This is certainly determined by low-charge resources such as nickel, aluminum, or metal. Additionally, the items manufactured by them tend not to call for large closing completing operations.

One of the biggest features of this particular digesting is the fact rotomolding polyethylene could lead to stronger elements with a decent shelf life. Irrespective of how very much this natural materials is commonly used by around 90% of the rotational molding market in the world.

A completely personalized service

Hardly any firms worldwide offer the Rotational Molding assistance offered by Granger Plastics Firm because it offers the last completing assistance after Molding, storing of elements, and dispatching these people to finish customers.